CARBIDE TOOTH GEOMETRY TECHNOLOGY

TECHNIK CARBIDE TOOTH GEOMETRY TECHNOLOGY

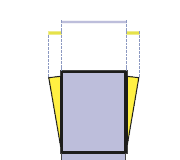

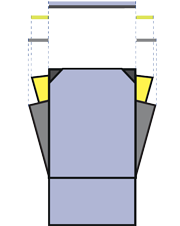

POWERCUT TOOTH (TP)

This carbide-tipped saw blade with a 3-tooth group (pre-cutter, mid cutter, finish-cutter) and a positive rake angle is particularly suited for tool steels, stainless steels, high-speed steels, chrome-nickel steels, nickel-based alloys, aluminium and all other steel qualities up to a strength of about 1600 N/mm2²

POWERCUT SN TOOTH (TPSN)

This carbide-tipped saw blade with pre- and finish-cutter and a rake angle of 0° is particularly suitable for induction-hardened/throughhardened materials with hardnesses from 50 HRc to 64 HRc which are cut on light band saws, and for steel qualities with strength up to about 1600 N/mm².

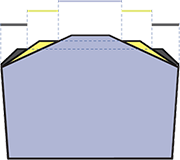

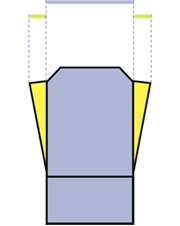

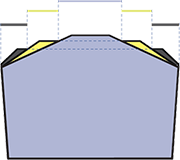

POWERCUT SET EXTREME (TPSE)

This carbide-tipped bandsaw blade with a stepped tooth set and a positive rake angle is particularly suitable for sawing materials under residual stress, up to a material strength of about 1600 N/mm².

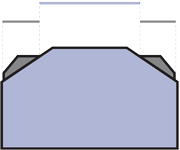

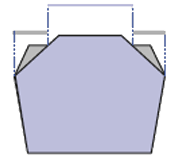

POWERCUT SET TOOTH (TPS)

The set carbide-tipped saw blade without a stepped tooth set and a positive rake angle is suitable for a wide range of materials up to a material strength of about 1600N/mm².

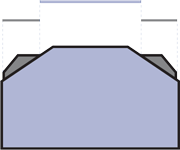

POWERCUT MULTIPLEX TOOTH (TPM)

This carbide-tipped bandsaw blade with carbide trapezoidal teeth is designed for sawing solid materials, pipes, square tubes and profile steels, from low-allow to high-alloy.

POWERCUT ALU 2 TOOTH (TPA2)

This carbide-tipped saw blade with pre- and finish-cutter is optimized for sawing non-ferrous metals, especially aluminium – cuts blocks, plates and sprues without difficulty.

POWERCUT ALU 3 TOOTH (TPA3)

This carbide-tipped saw blade with pre-cutter, centre cutter and finish-cutter is particularly well designed for sawing blocks and plates made of non-ferrous metals, especially aluminium. The unique tooth geometry delivers a perfect sawing surface.

POWERCUT TCO TOOTH (TPCO)

This set carbide-tipped saw blade without a chamfered pre-cutter is suitable for sawing aerated concrete and insulating materials.