BIMETAL TOOTH GEOMETRY TECHNOLOGY

BIMETAL TOOTH GEOMETRY TECHNOLOGY

RAKER TOOTH (N)

A tooth shape with a rake angle of 0°. It is particularly suitable for sawing short-chipping materials, low-alloy materials and small and medium cross-sections of solid materials, as well as pipes and beams.

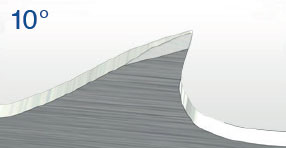

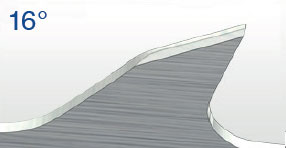

HOOK TOOTH (K), (K+)

The hook tooth with a positive rake angle of 10° or 16° K+ has a large, elongated chip space. Therefore, it is preferred for use cutting non-ferrous metals, low-carbon steels and CrNi alloys.

MASTER TOOTH (M), (M+)

The master tooth M with a positive rake angle of 10° or M+ 16° has sharpened tooth tips with one chamfered, unset pre-cutting tooth and two set finish-cutting teeth. The special tooth geometry allows economical sawing of high-alloyed and ultra-high-alloyed steels with bi-metal bandsaw blades.

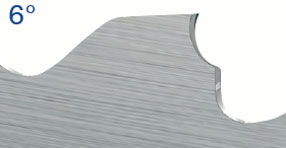

PROFILE TOOTH (P)

The profile tooth with a positive rake angle of 6° has a longer drawn tooth back. Its special geometry makes it especially suitable for profiles and beams under residual stress.

PIPE TOOTH (PP)

The PIPE tooth with a positive rake angle of 6° has a longer tooth back and a chip breaker. Its special geometry makes it particularly suitable for thick-walled pipe applications.